The ship's engineering plant served many functions: it propelled the ship through the water; distillation plants produced pure water for drinking and to supply the boilers; generators provided electricity for the ship; fans moved air into the closed spaces in the ship; air conditioners and heaters maintained a comfortable temperature; anchor windlasses raised and lowered the anchors; pumps moved water throughout the ship for drinking, fire fighting and dewatering spaces; steering gear powered the rudder for maneuvering the ship; and the gyro compasses aided navigation.

All other systems in the ship depended upon the engineering plant. The Engineering Department operated and maintained the many of the complex and interdependent systems on the ship. It was a never ending 24-hour-a-day and seven-day-a-week job.

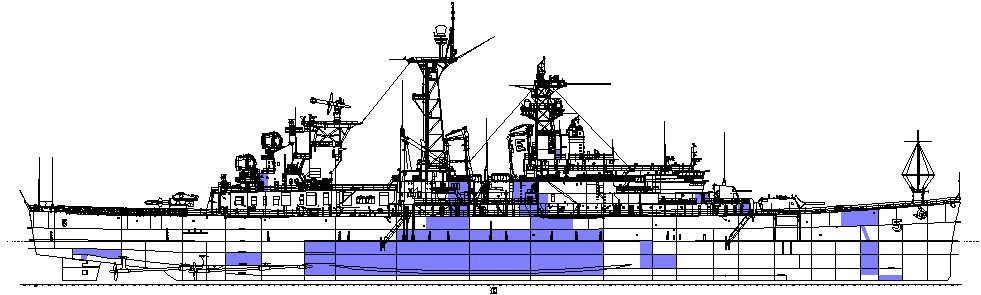

The propulsion plant and the major auxiliary machinery are described in the separate pages listed below:

- Propulsion Plant The Propulsion Plant provided the power to move the ship through the water.

- Auxiliary Equipment Auxiliary equipment provided many important functions.

- Hydraulic Equipment Hydraulic equipment powered much of the larger machinery.

In addition to the major engineering equipment the ship had many other systems that were necessary for operations.

The ship had an extensive communications systems with many different circuits dedicated for specific tasks. The ship's 1MC system was a general announcement public address system with speakers located in every compartment and on the open decks. Other systems were used for weapons control, damage control, engineering, lookouts and communications between specific compartments like the Bridge, Combat Information Center, Weapons Control, Gun Plot, etc.

Just about every passageway and compartment on the ship had electrical cables on the overhead and bulkheads. The electrical system supplied power for the lights, vent blowers and most other equipment and machinery throughout the ship. Much of the system had parallel branches so damage at one point would not affect other parts of the ship. All of these circuits could be switched individually between the main switchboards in the fire rooms, and many could be powered by the emergency diesel generators.

Air was drawn into the ventilation system through large blowers located in fan rooms in the superstructure. The system had ducts to supply breathable air to every compartment that was occupied by the crew and to storage compartments that the crew visited regularly. Numerous electric motor powered ventilation blowers were scattered throughout the ship to keep air flowing - the hum of these motors and the hiss of air flowing from the vents was a constant noise throughout the ship. If airflow stopped the spaces that had no direct openings to the outside atmosphere, especially compartments low in the ship's hull, would soon be depleted of oxygen and the carbon dioxide levels could increase to dangerous levels.

The ship's refrigeration plant included air conditioning machinery rooms and refrigeration units for food coolers and storage compartments. In addition to the main air conditioning equipment many smaller air conditioners had been installed in passageways.

The steam system delivered auxiliary steam throughout the ship to power some equipment, provide heat for cooking and heating for living and work spaces.

The firemain system delivered sea water to fireplugs, flushing systems, sprinkling systems and machinery cooling systems. Two parallel systems ran through the ship so if one was damaged the other would still supply water for fire fighting.

Fresh water pipes ran to scuttlebutts (drinking fountains) and heads (toilets, sinks and showers) throughout the ship. Drain pipes from the scuttlebutts and heads carried the waste water overboard. Water to flush the toilets came from the flushing system that drew water from the firemains.

Magazines, turrets and missile spaces had sprinkling systems that were automatically activated if the temperature or pressure in the spaces rose suddenly. These were dry pipe systems that did not carry water unless the control valves were activated. Water for the sprinklers came from the firemains. The sprinkling systems were tested periodically by bypassing the delivery pipes at the output of the control valves and running the water overboard.

The water washdown system carried sea water from the fire mains to spray heads on the exterior of the ship. These were positioned so the entire topside exterior surface of the ship could be washed. The purpose was to wash away fallout from nuclear explosions. If the ship entered a radioactive cloud all doors, windows and air ports would be closed, the ventilation system would be shut down, and the washdown system activated to remove radioactive contamination from the ship.

The engineering plant supplied compressed air to parts of the ship. Water traps were located throughout the system to remove condensed water from the air pipes. Air driers removed remaining water vapor. The missile house had a lot of pneumatic machinery that was driven by compressed air.

The fuel oil system included the fuel oil tanks, piping, pumps, heaters, and strainers. The tanks were part of the ship's structure, mostly located in the double or triple bottom around the outside of the hull below the waterline.

Ballast tanks and some fuel oil tanks were connected to the ballasting system to allow water to be pumped into the tanks for stability control. The ballast system had pumps and eductors to remove water from the tanks.

With all of these systems running throughout the ship to every compartment the passages and overheads carried a tangle of cables and pipes. Each was labeled to make it possible to locate a specific circuit for maintenance. Valves and switch boxes made it possible to reroute some of these circuits to bypass damage.

In addition to these systems the ship had a laundry, machine shops, metal shops, pipe shops, carpenter shops, gyro compasses, fire fighting systems, damage control equipment and the ships boats. All of these were maintained by the Engineering Department, and the engineers also performed structural maintenance and repairs to ensure water tight integrity of the hull.

References

1. Principles of Naval Engineering, NAVPERS 10788-B, Bureau of Naval Personnel,1970.2. Blueprints for the original Cleveland class ships and for the CLG Talos modifications.